Data-driven Controls for Water Quality in Industrial Manufacturing

- 4.6 Avg. Industrial Customer Rating

KETOS is transforming how water operators in industrial manufacturing organizations measure, track, and control acute limits for water contamination (including heavy metals like lead, mercury, and arsenic) in real-time

Water Quality Analytics for Industrial Applications

Real-time intelligence and process controls for water quality are essential to any manufacturing process and critical to ensuring uptime and product quality during industrial processes in industrial manufacturing, oil and gas extraction, or power plant operations. In today’s ever-restrictive regulatory environment and under enhanced public scrutiny, KPIs, data, and reporting are more important than ever when maintaining acceptable water quality. By being vigilant, operators reduce compliance costs, protect against contamination events, and lower chemical usage. Being better at water management starts with having real-time visibility into water quality at any given time across operational processes, and that visibility becomes possible with KETOS.

Modern operations can no longer rely on manual sampling and third-party lab analysis. The old way of operating is just too slow and often too cumbersome, requiring more personnel and delayed results that can slow down reaction times when companies need to act fast.

Proper water quality monitoring is essential within industrial facilities to ensure that water used for boilers, cooling, wastewater, or other industrial water systems is sufficiently managed. Better water management means less downtime, more efficient equipment maintenance scheduling, reduced chemical usage, and less general wear and tear on infrastructure. However, only a comprehensive, proactive monitoring system can ensure product quality, prevent unscheduled downtime, and allow water managers to detect and respond to events before a potential shutdown.

Compliance in industrial manufacturing is also an important aspect when tracking water quality. KETOS makes regulatory compliance – particularly for effluent, produced, and recycled water – more transparent and straightforward. Water operators can quickly catch contamination events or parameter spikes by tracking quality in real-time. This helps protect organizations against non-compliance and maintains internal safety and sustainability standards.

Save Time, Money, and Resources with KETOS

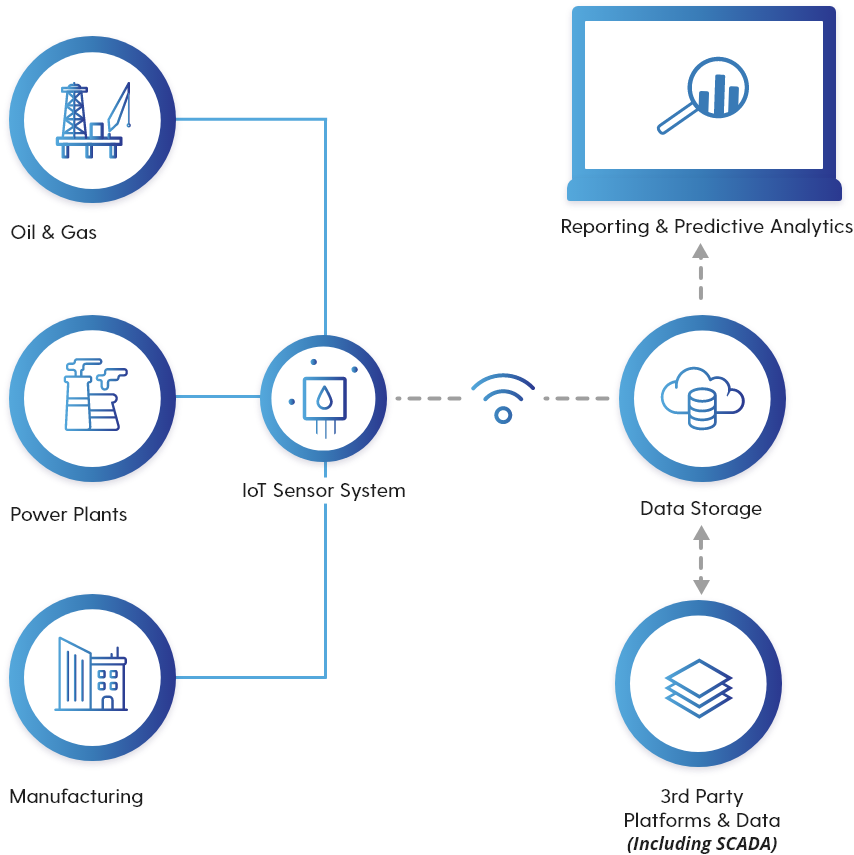

KETOS enables water operators to automate water quality testing and monitoring. Utilizing robust hardware (for physical sampling) and cloud-enabled software (for analysis and reporting), the vertically integrated platform helps water operators gain more real-time insights into their water quality. The system is modular and interoperable, meaning KETOS devices can be placed strategically across your industrial water infrastructure while seamlessly connecting other systems (like HACH and SCADA) to centralize data and collect real-time parameter readings for one low monthly fee.

Because the KETOS solution is fully integrated, it includes real-time threshold-based alerts and reporting with parts per billion (ppb) specificity and industry-standard lab accuracy. Water operators can choose from 30+ (and counting) parameters to customize their monitoring and reports. Once customized, KETOS will begin to pull samples at pre-determined intervals, and the data collected can instantly identify and alert users of water quality and usage to ensure product quality, consistency, and reliability.

KETOS hardware can be used in various scenarios (wastewater, process water, processed water, influent, effluent. Its rugged design also works well in challenging conditions (including outdoors and at high and low temperatures), making it the perfect solution for industrial applications that may have water infrastructure that is remote or has exposure to outdoor conditions (for example, oil and gas fields, ash and tailing ponds, mining operations, etc.).

How KETOS Works

Increased ROI Across Industrial Manufacturing Operations

- Identify issues before they impact product quality

- Reduce the risk of compliance violations

- Ensure water efficiency and quality - inlet, effluent, produced, and recycled water

- Eliminate manual sampling, testing, and recording

- Reduce man hours for sampling and redirect staff to more high-value tasks

- Significantly reduce cost per sample

Oil & Gas

Discover How You Can

Discover How You Can

operate consistently & predictably

Operate consistently without having to calibrate, clean and repair failed instruments

Mining

Discover How You Can

Discover How You Can

Ensure Compliance

Identify anomalies and pre-empt potential compliance issues

Manufacturing

Discover How You Can

Discover How You Can

Eliminate time & Expense of manual testing & reporting

Establish proactive testing and treatment processes