Learn How Automated Water Sampling Saves Cities & Businesses Hundreds of Hours Each Year…

PFAS Exposure In the USA

WEBINAR: Operational Value of Water Quality Intelligence in Agriculture

Oct 23, 2024 at 11:00 AM EST

Prevent downtime by monitoring for certain parameter spikes. Set threshold alerts and get notified so you can take action in real-time.

Keep the infrastructure you have and make it better with KETOS. Our solution plugs right into your water systems and helps prevent data silos.

Test for 30+ parameters, including total hardness, temperature, dissolved solids, heavy metals (copper, iron, etc.), and more.

Leverage automation for testing at regular intervals to better understand your organization’s usage and water quality.

Use less water in your operations, protect equipment, balance chemicals used, and recycle water more effectively.

Get an accurate real-time view of water quality for more streamlined operations and better overall water quality.

One of the largest multinational automotive manufacturing organizations in the world required a solution that could ensure NPDES permit compliance, meet corporate sustainability expectations, and increase water reuse while decreasing the use of fresh and groundwater sources. Find out how KETOS helped this automotive manufacturer overcome these challenges while gaining more visibility into their water quality.

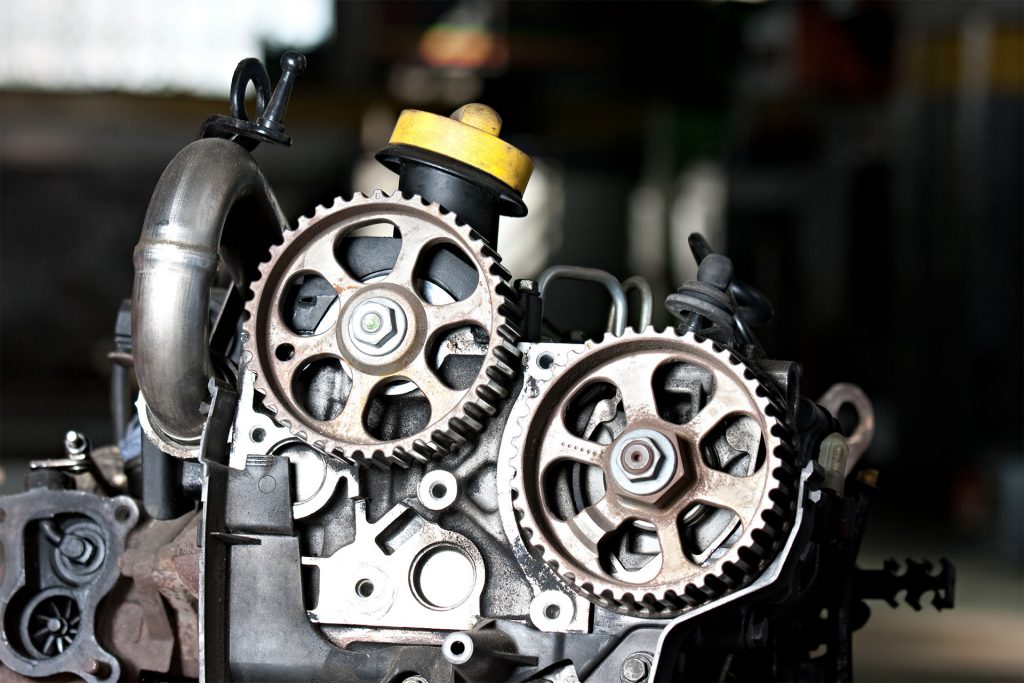

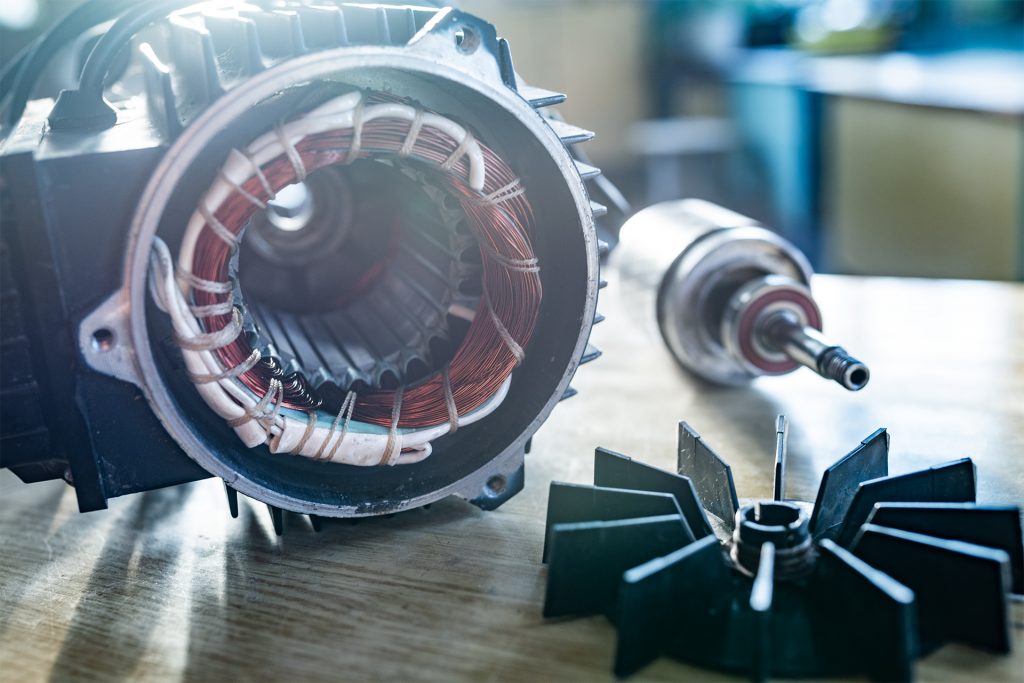

Water quality monitoring is vital for automotive manufacturing. It ensures seamless operations across all shifts. However, maintaining a specific level of quality is also a stringent requirement when dealing with and discharging process water.

Automotive manufacturing continues to be a water-intensive process. Additionally, many multinationals have the added pressure of working towards lower consumption and more recycling to align with corporate sustainability goals. However, plant operators have a two-fold challenge: how to ensure manufacturing lines have as much uptime as possible while being as efficient and sustainable with their water usage as well.

Water quality monitoring automation helps with both challenges. Automotive manufacturers can closely monitor the water quality in their process water and boilers (to maintain healthy equipment). They can also study their usage to remove impurities more effectively at discharge and use gathered historical data to find ways to build more in more efficient water usage.

With KETOS, automotive manufacturing organizations get:

With KETOS, companies gain more control over their water. As a result of implementing a KETOS product, water operators can act faster when quality changes happen to increase uptime and keep operations running smoothly across every shift – while still working towards more environmentally sustainable practices.

"*" indicates required fields

Subscribe to our newsletter to stay updated with the latest water insights.

"*" indicates required fields

Copyright © All rights reserved.