Learn How Automated Water Sampling Saves Cities & Businesses Hundreds of Hours Each Year…

PFAS Exposure In the USA

WEBINAR: Operational Value of Water Quality Intelligence in Agriculture

Oct 23, 2024 at 11:00 AM EST

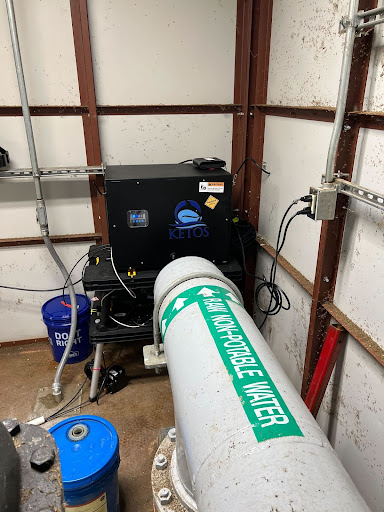

Chemical manufacturing requires proactive testing to maintain compliance. However, the process of water sampling can be expensive and labor-intensive. With automation via KETOS, organizations are finding game-changing efficiencies for day-to-day operations.

Prevent downtime by monitoring for certain parameter spikes. Set threshold alerts and get notified so you can protect batches and equipment in real-time.

Automate testing to remove the need for on-site manual sampling and expensive third-party lab analysis.

Test for 30+ parameters, including total hardness, temperature, dissolved solids, heavy metals (copper, iron, etc.), and more.

KETOS devices self-clean and calibrate, and KETOS covers maintenance requirements for equipment via a low, monthly, $0-CAPEX fee.

Automated testing and reporting allow operators to catch problems quickly and comply with local regulations.

Get an accurate real-time view of water quality for more streamlined operations and better overall water quality.

A Fortune 500 multinational conglomerate chemical manufacturer had been cited in litigation related to health and environmental complaints. As a result, the plant operations team needed to proactively understand the composition of its water matrix on a 24/7 basis. Learn how they were able to leverage historical views, trend analysis, and even predictive intelligence to improve water quality, site operations, and overall efficiency.

"*" indicates required fields

Subscribe to our newsletter to stay updated with the latest water insights.

"*" indicates required fields

Copyright © All rights reserved.