Learn How Automated Water Sampling Saves Cities & Businesses Hundreds of Hours Each Year…

PFAS Exposure In the USA

WEBINAR: Operational Value of Water Quality Intelligence in Agriculture

Oct 23, 2024 at 11:00 AM EST

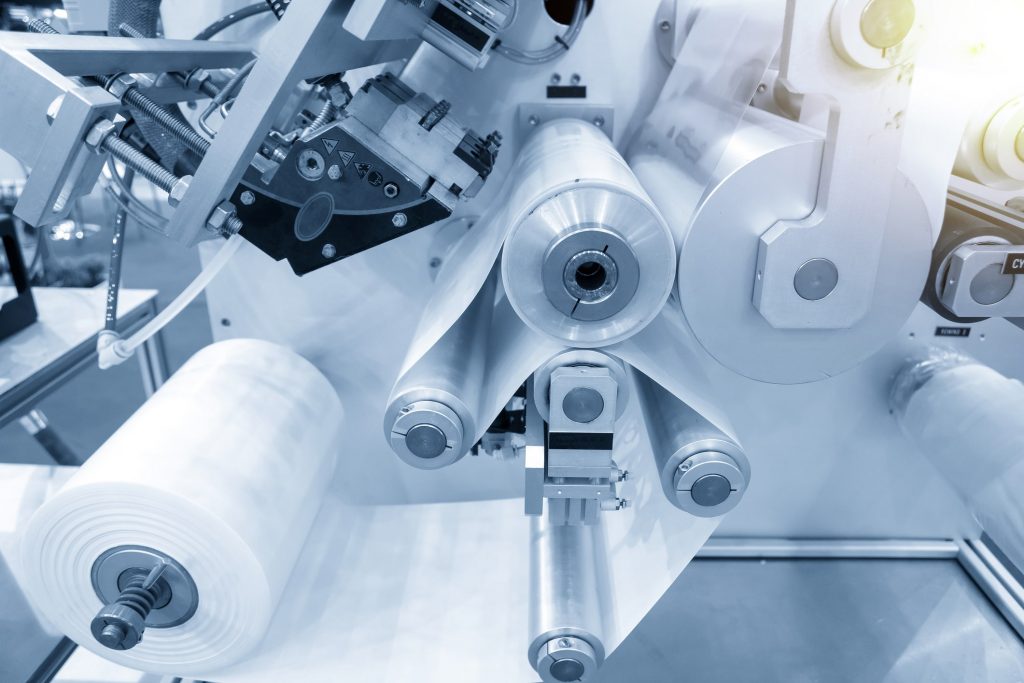

Consumer Goods manufacturing can grind to a halt when water quality is out of balance, which makes maintaining it essential to daily operations. Automating water quality can save thousands of dollars a month and dozens of hours of unexpected manual labor costs.

Leverage automation for testing at regular intervals to better control water conditions to avoid equipment downtime.

Monitor for certain parameter spikes. Set threshold alerts and get notified so you can take action in real-time.

Keep the infrastructure you have and make it better with KETOS. Our solution plugs right into existing systems to prevent data silos.

Test for 30+ parameters, including environmental factors, heavy metals (copper, iron, etc.), inorganics, and more.

Use less water in your operations, protect equipment, balance chemicals used, and recycle water more effectively.

Get an accurate real-time view of water quality for more streamlined operations and more informed decision-making.

To meet deliverables expectations, consumer goods manufacturers need to ensure their operations have as close to 100% uptime as possible. Learn how one Fortune 500 consumer goods manufacturer leverages KETOS SHIELD to improve water quality, uptime, and production capacity – while gaining a 15% rate of return.

Water operators in Consumer Goods manufacturing have deliverables and quotas they need to hit to ensure contract fulfillment. Any unscheduled downtime can throw off expectations. One primary challenge for many companies, for example, is boiler uptime. If a boiler is down, it has a knock-on effect across shifts and operations. The health of process water is also a concern, as is the balance of chemicals in mill tanks.

However, boiler uptime, mill tanks, and process water are manageable with careful, balanced water treatment. By automating water quality testing, water operators can quickly assess the health of boiler water to keep chemical balances in line with optimal operational efficiency. Automating water testing also allows operators to set threshold alerts to get immediately notified if there’s a spike in specific parameters (like total harness, orthophosphates, calcium, and more).

With KETOS, consumer goods water operators get a solution that can:

KETOS doesn’t just automate the on-site water quality monitoring. Instead, it allows organizations to keep their water data in-house and removes the need for third-party testing and reporting. As a result, companies gain more control over their water quality and can act faster on water quality changes to increase uptime and keep operations running smoothly across every shift.

"*" indicates required fields

Subscribe to our newsletter to stay updated with the latest water insights.

"*" indicates required fields

Copyright © All rights reserved.