Autonomous Industrial Wastewater Analysis

Problems Solved Before They Happen

Never Miss A Test

There’s no longer a need to rely on operators to grab samples, send samples to a lab, or run tests in the field. Schedule the SHIELD to test water on a schedule that best suits your needs.

Immediate Results

No more waiting for test results. Know if your water meets safety, quality, and compliance standards in real-time.

Monitor From Anywhere

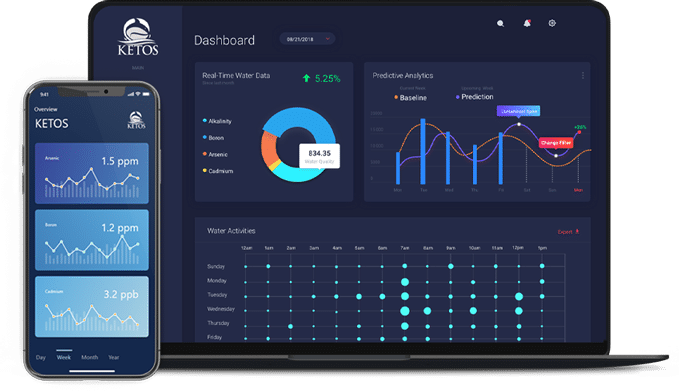

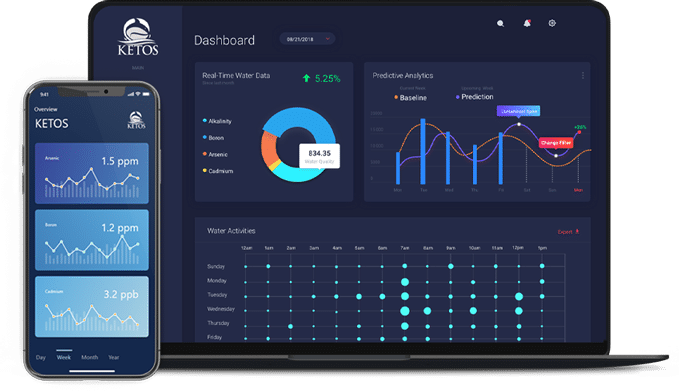

No manual sampling testing, calibration, or clearing required. KETOS is completely autonomous and delivers real-time data to your device – anytime, anywhere.

Overview

KETOS: Remote Water Quality Monitoring

Sampling

Testing

KETOS tests water quality across dozens of parameters including environmental, inorganics, nutrients, and heavy metals and delivers lab-accurate results in real-time. Additional parameters are continuously added.

Calibration and Cleaning

Reporting and Alerts

Analyze

Learn How KETOS Could Work for You

Lab-Accurate Water Quality Data in Real-Time

KETOS Awards

Industrial Wastewater

Water is required for nearly every step of production in many commercial and industrial manufacturing processes. As water is used in manufacturing operations and productions, it can become contaminated due to contact with pollutants. Industrial wastewater can also refer to other liquid carried waste generated during industrial or commercial manufacturing or processing operations. Therefore, wastewater discharged after being used in an industrial or commercial process may contain pollutants at harmful levels that might prove dangerous. The definition of pollutants under the Clean Water Act is broad and covers multiple sources. According to the United States Environmental Protection Agency (EPA), a pollutant is any type of industrial, municipal, and agricultural waste discharged into water. Some examples are contaminated soils, solid waste, incinerator residue, sewage, sewage sludge, munitions, chemical wastes, biological materials, radioactive materials, heat, wrecked or discarded equipment, rock, sand, and industrial, municipal, and agricultural waste. This industrial waste water pollution might also be harmful to public wastewater treatment plants situated downstream and might not be equipped to handle the type of contaminants the discharged wastewater might contain.

Industrial wastewater sources can include chemical manufacturing, oil and gas refining, energy production, cooling water, mining, metal manufacturing, food and meat production, pulp and paper manufacturing, clothing and textile manufacturing, and any other process that requires water to complete. Sources of industrial wastewater, industrial and commercial operations, must ensure that effluent discharged from their operations complies with existing laws and permitting requirements. The National Pollutant Discharge Elimination System (NPDES), administered by the EPA, serves as the primary mechanism for controlling the discharge of pollution to bodies of water in the United States. To comply with NPDES requirements, any chemicals or pollutants used in industrial production that might be present in discharged effluent must be monitored for, and removed, if levels exceed safe concentrations. The established acceptable concentrations for known chemicals and contaminants are based on the degree of attainable pollution reduction using current technology and treatment processes.

Types of Industrial Wastewater

Industrial wastewater contains different potential pollutants or contaminants when compared to domestic wastewater. Domestic wastewater’s primary pollutants are pathogens, plant nutrients, and oxygen-demanding wastes. Industrial wastewater discharge can be divided into two broad categories, conventional and toxic. Conventional contaminants can impact water quality like high amounts of suspended solids, the pH of water, oil, grease, pathogens, and oxygen-demanding bacteria. Toxic pollutants can include heavy metals, organic and inorganic chemicals, solvents, surfactants, degreasers, and other byproducts of industrial manufacturing and production processes. Different types of industrial wastewater are produced by various industries. For example, the wastewater generated from a mining operation will differ from that which originates at a chemical manufacturing plant. Because of this, wastewater must be sampled frequently to comply with NPDES and Clean Water Act (CWA) stipulations for industrial wastewater discharges and to ensure natural environments, waterways, and human populations are kept safe.

The mining, oil and gas, food production/meat processing, pulp and paper milling, and chemical manufacturing industries produce different types of wastewater.

Mining

Water is used in both mining operations and milling ores obtained during mining. The wastewater produced from these activities can contain heavy metals. In addition, the byproducts of the mining and milling processes called tailings, a mixture of water and finely ground rock left over from the milling process, are stored in impoundment structures. The water in these structures can be dangerous if it leaches into surrounding aquifers or waterways.

Oil and Gas

Large volumes of wastewater are generated from oil and gas mining. This is from two primary sources: water introduced during the hydraulic fracturing method of oil and gas extraction and water in aquifers adjacent to or in layers of sediment containing petroleum products. This water can have large amounts of chemicals due to the fracking process and being in contact with oil or gas for millions of years. This water can also be highly saline, and in some locations, it might even be slightly radioactive.

Food Production/Agriculture/Meat Processing

Agricultural, meat processing, and food production wastewater can contain different harmful chemical, biological, and pathogenic wastes. High concentrations of pesticides, insecticides, fertilizers, and animal waste can all be present in these wastewater streams. Food production can result in water with high particulate levels and organic chemicals. Meat processing can lead to high nutrient levels in the water. These different contaminants need to be sampled and treated before the effluent can be discharged.

Pulp and Paper

The primary pollutants from pulp and paper production are solids that affect water chemistry and organic matter. In addition, different production processes result in various contaminants. This comes from low oxygen levels in the water, increased turbidity, high or low pH levels, high temperatures, and high chlorine levels. If this water is discharged without proper treatment, adverse effects to natural and aquatic environments, wildlife, and other downstream users.

Chemical Manufacturing

Water used for chemical and pharmaceutical manufacturing can become highly contaminated with organic, inorganic, and toxic substances. In addition, the wastewater from these manufacturing processes can contain toxic, mutagenic, carcinogenic, and non-biodegradable substances. Therefore, understanding what is included in these wastewater streams and at what concentrations is critical to ensure that harmful byproducts or polluted wastewater are contained and treated.

Industrial Wastewater Characteristics

Industrial wastewater composition will vary across different industries and be determined by the production or manufacturing processes. As previously discussed, these industrial wastewater characteristics will differ from domestic wastewater characteristics. As a result, domestic wastewater differs in its composition, what hazards might be present, and treatment strategies required when compared to industrial and commercial wastewater.

Below, the different characteristics and hazards of wastewater from various industries are discussed.

Mining

Mining wastewater can be highly acidic and contain high amounts of suspended solids. Heavy metals and metalloids like mercury, arsenic, iron, zinc, cadmium, and manganese are common contaminants in mining wastewater. Conversely, wastewater from coal mining can be unacceptably saline and require desalination.

Oil and Gas

Hydraulic fracturing wastewater includes dissolved oil, hydrocarbons, hydrogen sulfide gas, acids, phenols, metals, and radioactive materials. Hydraulic fracturing additives can be carcinogenic and hazardous if they leach into drinking water supplies. Over 1000 chemical additives have been used for hydraulic fracturing, 27 of which have been classified as carcinogenic by the U.S. EPA.

Food Production

Different food and agricultural production processes create different types of wastewater, but most contain high amounts of nitrogen, nitrates, suspended and dissolved solids, organic carbon, and potentially high levels of pathogens. High nutrient levels in the effluent stream can also be detrimental or dangerous for waterways or downstream treatment plants if the effluent is discharged into a sewer system. The food production industry is the leading source of discharged industrial waste in the U.S.

Pulp and Paper

Pulp and paper wastewater streams can contain high levels of inorganic pollutants like copper, zinc, nickel, mercury, and magnesium. In addition, the wastewater streams often have high amounts of suspended and dissolved solids, can be at elevated temperatures, and can contain high levels of phenols. Large quantities of chlorinated compounds can also be present in pulp and paper wastewater streams.

Chemical Manufacturing

The chemical and pharmaceutical manufacturing industries are extensive and use many different toxic substances. Therefore, wastewater from these facilities must be carefully sampled and monitored to prevent the release of toxic substances into traditional wastewater disposal streams like domestic or municipal sewer systems. Unfortunately, municipal wastewater treatment plants are often not equipped to handle the specific toxic chemicals released from these manufacturing and production facilities.

Understanding industrial wastewater characteristics is critical to ensure that adequate sampling, monitoring, and treatment programs are enacted. This can prevent the discharge of harmful substances into wastewater streams where they cannot be treated, harming natural environments, disrupting ecosystem services, and endangering human populations that might encounter polluted wastewater.

Impacts of Industrial Effluents on Environment and Humans

The negative effect of industrial wastewater on the environment due to the release of toxic and harmful substances into waterways and sewer systems can take years or decades to identify and mitigate. For example, the Cuyahoga River flows through Cleveland, Ohio, and into Lake Erie. For decades, the river was heavily impacted by industrial pollution and was often covered in a sheen of oil and other unknown toxic substances discharged from industrial manufacturing facilities along its banks. As a result, the river’s surface caught on fire at least 13 times, with the most well-known of these occasions in June of 1969. This fire, caused by a spark from a locomotive landing on the polluted river’s surface, led to a massive environmental protection push to clean up polluted waterways.

Previously discussed industrial wastewater examples from the mining, oil and gas, food and meat processing, chemical manufacturing, and pulp and paper industries can all have significant negative and long-lasting impacts on natural environments, disrupt ecosystem services in delicate aquatic and wetland locations, and pose serious health risks to downstream human populations. Some organic and inorganic contaminants, such as heavy metals and pesticides, are severe threats to ecosystems and humans because of their toxicity at low levels. These contaminants, some of which do not biodegrade over time, can accumulate in living organisms and increase concentration over time through biomagnification. This is particularly of concern with so-called “forever chemicals,” also known as per- and poly-fluoroalkyl chemicals (PFAS), which do not break down over time once they have been released into a body of water. Furthermore, industrial wastewater effects are not limited to only bodies of water. Because of environmental interactions, harmful impacts on the water can also be felt in soils and the atmosphere. Practical and intelligent monitoring policies and procedures utilizing the newest technology available are essential to mitigate the harmful impact of industrial effluents on environment and humans.

Industrial Wastewater Treatment

Autonomous industrial wastewater analysis streamlines monitoring by providing real-time, accurate data to ensure compliance and efficiency.

Autonomous industrial wastewater analysis streamlines monitoring by providing real-time, accurate data to ensure compliance and efficiency.The industrial wastewater treatment process will vary depending on the effluent stream’s type and amount of contamination. The variation in characteristics of industrial wastewater can be broken down into broad categories: physical traits, oxygen amount, presence of toxic chemicals, eutrophication, and presence of pathogens. Industry-specific wastewater treatment is required to ensure that release parameters for NPDES permitting are met. The industrial wastewater treatment process must be tailored according to the source and the characteristics of the effluent stream. The end goal of treatment, either recycling back into manufacturing and production processes or release into a municipal water treatment system or waterway, will also play a determining factor in the treatment process. To prevent previously discussed environmental and health issues that industrial wastewater discharges can create, it is necessary to eradicate its toxicity using physical, chemical, and biological treatment methods. A new industrial wastewater treatment plant will use chemical, electrochemical, biological, and physical processes to ensure that any released effluent is safe and meets all parameters dealing with NPDES regulations.

Real-time analysis of effluent streams can ensure that compliance is maintained without waiting for lab results and can be critical in detecting failures within a treatment operation and safeguarding downstream communities. Industrial wastewater plants are often located on-site because the wastewater cannot be discharged until at least some preliminary treatment has been conducted. Cooling towers are used to remove excess heat from water used for cooling, and constructed wetlands provide secondary treatment in some cases.

Safe treatment and disposal of industrial wastewater are complex because of the variable nature of contaminants present. Lowering or eliminating levels of toxic compounds before effluent discharges take place is critically important to ensure that natural resources, ecosystems, and human populations are safeguarded. Real-time autonomous industrial wastewater monitoring offers a way to ensure that these environments and people are protected in a timelier manner than was previously possible with traditional methods of grab sampling and waiting for the results to be returned from a lab. Quick responses to failures in treatment operations can be realized by utilizing this new technology, which ultimately means that essential and imperiled water resources can be better protected.