Addressing Wastewater Compliance with Real-Time Data

Problems Solved Before They Happen

Never Miss A Test

There’s no longer a need to rely on operators to grab samples, send samples to a lab, or run tests in the field. Schedule the SHIELD to test water on a schedule that best suits your needs.

Immediate Results

No more waiting for test results. Know if your water meets safety, quality, and compliance standards in real-time.

Monitor From Anywhere

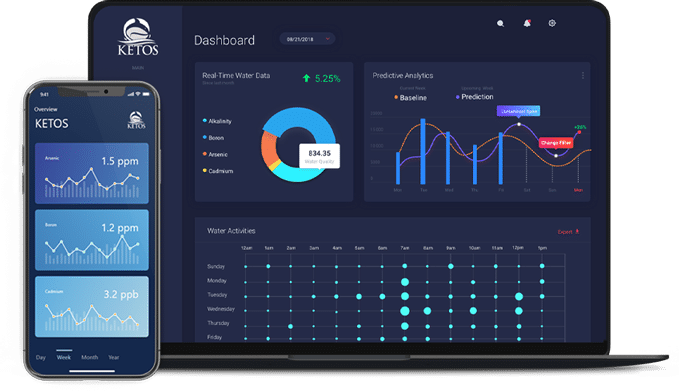

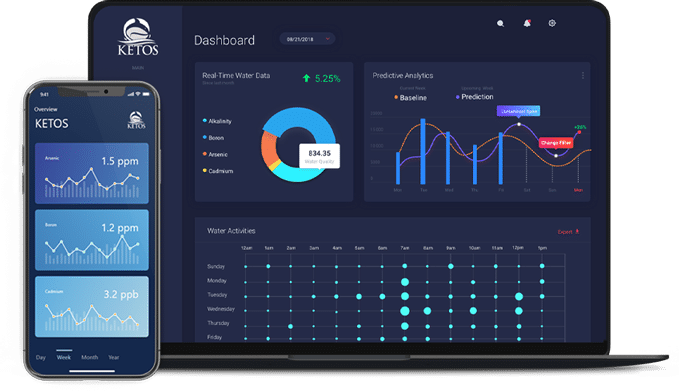

No manual sampling testing, calibration, or clearing required. KETOS is completely autonomous and delivers real-time data to your device – anytime, anywhere.

Overview

KETOS: Remote Water Quality Monitoring

Sampling

Testing

KETOS tests water quality across dozens of parameters including environmental, inorganics, nutrients, and heavy metals and delivers lab-accurate results in real-time. Additional parameters are continuously added.

Calibration and Cleaning

Reporting and Alerts

Analyze

Learn How KETOS Could Work for You

Lab-Accurate Water Quality Data in Real-Time

KETOS Awards

Wastewater Compliance

Wastewater compliance varies widely from country to country and even within states, provinces, and regions. However, wastewater is a sizable issue no matter where you are.

In terms of global wastewater statistics, there are an estimated 360 billion cubic meters annually – and approximately 48% is released directly into the environment completely untreated. One way to lower global wastewater generation is to reuse the water itself. However, only 11% of the globally produced wastewater gets reused. In the developing world, the main issue is the lack of financial resources available to build the necessary resources to collect and treat wastewater. While we may be under the impression that the US has infinite funding to handle wastewater management, that isn’t the case either. Advanced treatment facilities can be prohibitively expensive. And yet, technology, when leveraged, can be a powerful ally in wastewater remediation.

Water quality and management play a significant role in developed and developing countries. Many countries establish their standards to protect their citizenry and respond to local water quality challenges. However, the World Health Organization (WHO) has also attempted to develop normative guidelines. However, WHO wastewater standards surrounding drinking water and the safe use of wastewater in agriculture and aquaculture develop in isolation.

Closer to home, the EPA has worked to develop effluent guidelines. They are also, in tandem, running studies related to landfills, electrical and electronic components, and nutrient removal and secondary technologies to continue to develop a more holistic understanding of wastewater challenges across the country. To that end, the EPA has developed Effluent Guidelines – national wastewater discharge standards. These guidelines are outlined according to individual industries and are technology-based regulations designed to help mitigate the most significant pollutant reductions possible in an economically viable way. Direct dischargers have their standards incorporated into the National Pollutant Discharge Elimination System (NPDES) with permits issued by regional EPA offices and the states themselves.

Types of Industrial Wastewater

There are various wastewater categories. The main differentiators of wastewater – are wastewater that contains sewage and wastewater that doesn’t. However, these two main categories can break down further. Types of domestic wastewater, for example, include water from toilets and greywater (water from kitchens, bathrooms, washing machines, and other household appliances). It may also, depending on the region, include some industrial wastewater.

Types of industrial wastewater vary widely as well. Industrial wastewater, generally, is defined as wastewater from industrial or commercial sources. This type of wastewater could affect the quality of receiving waters (such as rivers, lakes, and streams) or utilities (publicly owned treatment works). The NPDES permitting program helps establish limits in terms of discharge related to industrial wastewater and the water condition requirements according to the type of facility or activity for industrial wastewater. There are specific NPDES requirements for:

- Mining

- Oil and gas

- Pesticide applications

- Animal feeding operations

- Fishing vessels

Beyond the NPDES requirements, however, industries are aware of what types of pollutants make up a more significant proportion of their wastewater and must find ways to remediate water in order to be able to return it, at acceptable levels, either to local public utilities (for further treatment), for reuse and recycling within their operations, or into the environment. Specific industries create certain types of wastewater, for example:

Chemical manufacturers

- Acids/bases

- Spent solvents

- Wastewater containing organic constituents

Oil and gas

- Hydrocarbons

- Benzene

- Sludge from the refining process

Construction

- Ignitable paint waste

- Acids/bases

- Spent solvents

Metal manufacturing

- Heavy metals

- Cyanide

- Paint waste

Wastewater Guidelines

The EPA effluent guidelines cover multiple areas of wastewater. They also have a Toxic Pollutant List (developed in 1976) (added to the 1977 Clean Water Act). The list is intended as a starting point for states to ensure Effluent Guideline regulations, NPDES permit requirements, and water quality standards nationwide. While Toxic and Priority Pollutant lists are somewhat outdated (for example, they have yet to take into consideration PFAS, or “forever chemicals” and may contain pesticides no longer used in the United States), consulting the lists happens when various parties develop ambient water quality criteria under the Clean Water Act (sections 303(c)(2)(B) and 304(a).

Globally, there are no clear and set wastewater guidelines that all countries agree to adhere to. However, both domestically and internationally, water management systems face the large-scale issue of accelerating water insecurity. Lack of proper sanitation is compounding wastewater management challenges for local communities, and the societal burden on human health is an issue worldwide.

That’s not to say that nothing is changing. The UN, for example, has found that for every US dollar spent on sanitation, the knock-on benefits to society amount to $5.50USD. While feasible and financially viable treatment of wastewater continues to challenge the global south, more international organizations are stepping in to pledge net-zero water usage in their industrial environments around the globe. As a result, many are adjusting their internal industrial wastewater discharge standards (where external regulations may not exist) to prioritize water reuse and recycling programs to help place less stress on local water supplies and reduce the total amount of created wastewater.

Wastewater Treatment Plants and More Effective Wastewater Treatments

While the private sector is working to reduce wastewater creation, public utilities are doing their part to become more effective. While new water treatment plants can redesign their capabilities to even more stringent standards, older facilities are still working on playing catch up in terms of modernizing their services.

The EPA and Clean Water Act dictates water quality standards, no matter the facility. Wastewater facilities have to operate according to specified permits from NPDES. An expected standard, for example, is the baseline for the Biochemical Oxygen Demand (BOD). While wastewater effluent typically has a BOD of 200mg/L, the treated effluent needs to have less than 30mg/L. A wastewater facility that does not meet these standards is at risk of penalty.

Therefore, wastewater must go through a thorough cleaning process. Wastewater is cleaned in multiple steps using a channel technique that makes water flow into channels from one central point. The design of a wastewater treatment plant ensures water increases in quality and cleanliness over multiple steps. These include:

- The removal of sizeable debris that may damage the facility’s physical infrastructure

- Forcing wastewater through a grit chamber to remove grit within the influent

- Initial separation of wastewater and organic matter

- Aeration

- Clarification

- The addition of chlorine

- Testing for pH, nitrates, phosphates, ammonia, dissolved oxygen, residual chlorine (etc.)

Once the wastewater has met all permit specifications, it’s ready for the surrounding environment. Wastewater testing happens at various points in the treatment process.

Wastewater Operator Certification Requirements

Another challenge for wastewater compliance is ensuring that personnel is certified and properly trained. However, in America, certification requirements vary from state to state. While training can vary widely, there are critical components of operator certification, including:

- Classification of operators/facilities/systems

- Qualifications for each grade or level

- Regular training to maintain certification

While training across the country addresses the EPA’s critical elements for operator certification, the training and language are far from standardized.

Another issue is that, due to a lack of uniformity, having the ability to correctly identify state operator certification requirements can prove challenging.

Why wastewater operation certification requirements may prove challenging to standardize may be related to the more significant variation in the classification of wastewater treatment systems. Water treatment, in contrast, is much more uniform. Many wastewater treatment systems are classified based on the complexity of wastewater treatment, yet the rating criteria are not the same, with point scales being different across states. Some may copy the approach of water treatment. Others may not. All of these points of differentiation play into differing approaches to certification. Therefore, each state has a different wastewater license lookup where it is possible to find what organizations or individuals and their licensing status.

Wastewater Compliance Systems, Data, and KETOS: Introducing Real-Time Water Compliance

KETOS delivers real-time wastewater quality analysis for compliance, efficiency, and sustainability.

KETOS delivers real-time wastewater quality analysis for compliance, efficiency, and sustainability.