Water Quality Analysis Methods And Automation

Problems Solved Before They Happen

Never Miss A Test

There’s no longer a need to rely on operators to grab samples, send samples to a lab, or run tests in the field. Schedule the SHIELD to test water on a schedule that best suits your needs.

Immediate Results

No more waiting for test results. Know if your water meets safety, quality, and compliance standards in real-time.

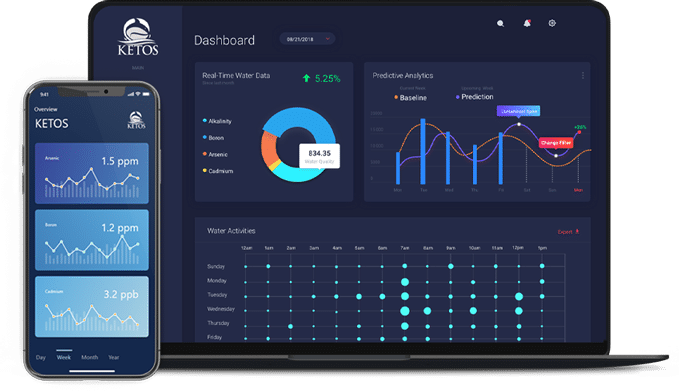

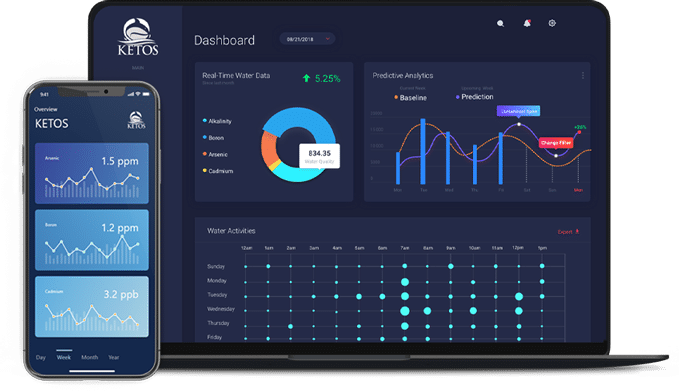

Monitor From Anywhere

No manual sampling testing, calibration, or clearing required. KETOS is completely autonomous and delivers real-time data to your device – anytime, anywhere.

Overview

KETOS: Remote Water Quality Monitoring

Sampling

Testing

KETOS tests water quality across dozens of parameters including environmental, inorganics, nutrients, and heavy metals and delivers lab-accurate results in real-time. Additional parameters are continuously added.

Calibration and Cleaning

Reporting and Alerts

Analyze

Learn How KETOS Could Work for You

Lab-Accurate Water Quality Data in Real-Time

KETOS Awards

Water Quality Analysis

Water quality analysis is integral to many manufacturing processes and can dictate production quality. Water cools equipment, sanitizes production areas, and acts as a conduit for chemical and dye delivery. Water quality analysis ensures communal drinking water supplies are free of contaminants such as lead, copper, and other pollutants. Water quality analysis introduction is integral to organizations that want to understand whether or not water meets critical compliance and safety standards.

Water quality monitoring use varies across industries, including:

- Agriculture, which uses water for irrigation, chemical delivery, cleaning, and cooling fresh-picked produce

- Vertical farming, which uses water in closed-loop systems that require careful balancing of nutrients

- Oil and gas that need water in various drilling and fracking processes

- Food production, which requires water for preparation and sanitization processes

- Meat processing which uses water extensively in the slaughtering and butchering processes and requires large amounts of water for sanitization of both carcasses and production areas

- Textiles where water helps with the cleaning, dying, bleaching, and de-sizing processes

- Technology, especially in data centers, where large amounts of water are required to cool racks and servers

- Utilities that must ensure the safety of drinking water supplies in communities

Water quality must be analyzed often and across processes to ensure safety and quality. It usually requires testing before, during, and even after use (in the case of recycling or remediation).

Water Quality Analysis Methods

Water quality analysis methods vary from organization to organization. There is not necessarily a standard analytical procedure for water analysis. For example, testing within various infrastructure setups may require different testing methods, and/or additional parameters or contaminants may require testing within specific areas, specific infrastructure, or within just one organization.

Some organizations leverage handheld probes. These mechanical devices must be carefully cleaned and calibrated. The use of hand-held probes also requires human intervention during testing. Human error can skew results if the probes are not properly stored, maintained, or used.

Other organizations also use manual water quality testing by manually pulling samples and shipping them off to a third-party lab for testing and analysis. While organizations often have protocols to ensure samples are not contaminated, tampered with, or lost – human error can and does happen. Labs are also costly, and results are slow to emerge. For example, some companies can wait days, weeks, or even months to uncover information about their organization’s water quality. Worse still, the delivery of data itself is often in a raw form that requires data scientists to translate the findings into meaningful information.

Technology has gotten better, and many organizations are beginning to invest in online or on-site analyzers. This equipment is much faster at pulling water quality information. However, often the equipment is so specialized that only a particular parameter (or set of parameters) is possible for monitoring within one technological intervention. Data, in most cases, often silos to one specific device. It’s not unusual, for example, for one device to monitor one parameter and for other devices to cover various others. More often still, the case is that these devices will be incompatible with each other. Therefore, it’s hard to pull in all necessary data across an organization’s infrastructure to get a complete picture of water quality. Data scientists and occasionally third-party assistance are still very much required even as in-house infrastructure costs rise with new (but limiting) technological interventions.

The KETOS solution answers these concerns directly via an interoperable solution and covers many necessary parameters all from one device. With KETOS, water operators can, for example, monitor for environmental factors (pH, temperature, ORPs), inorganics (alkalinity, fluoride, chlorine), or nutrients (nitrates, orthophosphates, nitrogen) at the same time they monitor for heavy metals (lead, copper, arsenic). With 30+ parameters (and counting), KETOS helps an organization cover every aspect of monitoring, all from one central place. It also plugs into other pieces of infrastructure and SCADA systems to centralize information while using all pre-existing infrastructure to maximum effect. Reporting is moved all to one place for a clearer understanding of the overall health of an organization’s water usage and quality.

Water Quality Analysis Parameters

Typical water quality parameters – physical, chemical, and biological – that are measured traditionally include:

- Dissolved oxygen (a key indicator, for example, in the health of streams and a potential sign of unhealthy levels of bacteria)

- Turbidity and total suspended solids (the clarity of water)

- Nitrates (a possible sign of human or animal waste contamination, industrial pollutants, or agricultural runoff)

- pH (in terms of how acidic or basic the water is)

- Temperature

In utilities, however, where direct human consumption is top of mind, water quality parameters for drinking water are stringent and could require testing for heavy metals – the most notable being lead. While lead pipes are no longer in use in more modern infrastructure, aging infrastructure across the country is still in the process of removal.

Water quality analysis parameters including chemical parameters of water quality require monitoring because of strict safety and regulatory compliance requirements. As a result, companies must keep a constant watch, and many seek solutions that help automate the process for water quality analysis for water quality parameters-physical chemical and biological parameters. For example, introducing technology can ensure testing for more parameters more often and with more accuracy. While, traditionally, companies would farm out data analysis to get water quality testing parameters recorded and deciphered, the process is notoriously expensive. In addition, it only allows companies to react to the findings days or weeks after the collected samples.

The EPA and Water Quality Analysis

The EPA outlines specific water quality parameters and standards, including specific levels of chemicals and conditions in water supplies that do not cause any adverse effects on overall human health. These have clear definitions under Section 304(a) of the Clean Water Act.

For example, the EPA outlines EPA water quality analysis requirements covering various contaminants – even down to micrograms per liter for 150 pollutants. They also develop rules for drinking water. For example, monitoring for lead and copper is required as a part of the Lead and Copper Rule.

The EPA has also developed a Standardized Monitoring Framework (SMF) to standardize, streamline, and consolidate the monitoring of contaminant groups. It reduces the variability within monitoring requirements and amplifies public health protection via synchronized monitoring schedules and simplified monitoring plans. Regulated contaminants under the SMF include 15 Inorganic Contaminants (IOCs) (such as Nitrate and Nitrite), 51 Synthetic Organic Contaminants (SOCs), and 4 Radionuclides.

The EPA also clearly outlines legal limits for 90+ potential drinking water contaminants. Once again, these legal limits are in place to protect human health and reflect the level of cleanliness that water systems can achieve using available technology. In addition, the rules involve setting testing schedules and other methods to which water systems must adhere.

Water quality, for the most part, is handled state by state. The Safe Drinking Water Act (SDWA) empowers individual states to set and enforce drinking water standards so long as the state itself meets the minimum requirements set by the EPA. Communities or regions might also have specific requirements, meaning organizations need to be mindful of regulations across multiple sources.

The Benefits of KETOS’ Water Analysis Software

The KETOS SHIELD automates water quality monitoring with real-time, lab-accurate data, replacing manual testing.

The KETOS SHIELD automates water quality monitoring with real-time, lab-accurate data, replacing manual testing.Due to federal, state, and local regulations, especially around drinking water, many organizations are opting to leverage water analysis software to help automate processes and reduce missed sampling or general human error. As a result, KETOS doesn’t just provide companies with an outdated water analysis report PDF. Instead, the KETOS platform uses on-site hardware and cloud-connected software to test in real-time for the most accurate up-to-date reporting visible at any time via online dashboards. Therefore, unlike traditional water analysis methods that must first pass data scientists the necessary information for analysis and reporting, water operators across industries can have immediate insights based on the water parameters they care about most. This real-time feedback loop allows for more responsive decision-making and a proactive approach to water management, contrasting with traditional water analysis methods that often involve significant delays in data processing and report generation.

KETOS hardware is self-calibrating and self-cleaning. It’s also modular, with companies installing the devices at strategic nodes throughout an organization’s infrastructure. In addition, each hardware component can be pre-programmed to test at regular intervals, monitor for threshold alerts, and cover 30+ parameters to ensure water quality is exactly where a company needs it to be – no matter the usage.

Having data accessible in real-time and stored safely in the cloud also means water operators from anywhere can access it. This makes water analysis of even remote areas even more accessible by saving time and costs by regularly sending personnel into the field to monitor and collect.

Reporting to stakeholders has never been easier as well. Dashboards are easily shared with management, for example, and can be used to show compliance with governing bodies. The information also creates a historical record that in-build AI and machine learning can take advantage of to spot trends and predict future events before they happen. This way, companies can get more thoughtful about their water and begin to act proactively instead of reactively when faced with water events on-site. Water quality analysis is indispensable in ensuring the safety and reliability of water across various sectors, from manufacturing to utilities, where stringent parameters such as pH levels and contaminants like lead are closely monitored to meet regulatory standards and safeguard public health.